Processing services – Professional, high-precision steel and metal processing

With our modern machinery, we process the products precisely according to your wishes.

Sawing and cutting

We cut steel and metal precisely to length, in Europe's most high-tech cutting and sawing centre.

Learn moreTube laser cutting

Thanks to laser technology, we are able to saw, drill, mill and deburr steel and metal in a single process step.

Learn moreFriction drilling

Using modern equipment, we realise chipless passages in thin-walled profiles.

Learn moreEdge and surface finishing

We deliver metal blanks deburred and free of rust, scale and rolling skin. If required, we can also provide blanks preserved, lasered or barrel finished.

Learn moreWhat is steel/structural steel used for?

In keeping with its name, steel/structural steel is ideally suited for steel engineering and machinery construction. It is used for a wide variety of applications, including:

- Steel-framed building construction

- Bridge building

- Machinery construction

- Automotive engineering.

Steel/structural steel is used in both solid and sheet metal form. Structural steels come in many different grades, which are divided into the following groups:

General steels/structural steels

General steel/structural steel is also known as iron or rolled iron and is the most common steel. It is used in metalworking shops, forges, in steel engineering and machinery construction in a wide variety of shapes, designs and dimensions as bars, profiles, tubes and sheets. Stairs, doors, railings and welded structures in vehicle and container construction, as well as civil engineering, bridge and hall structures are fabricated from this metal.

Weathering steels/structural steels

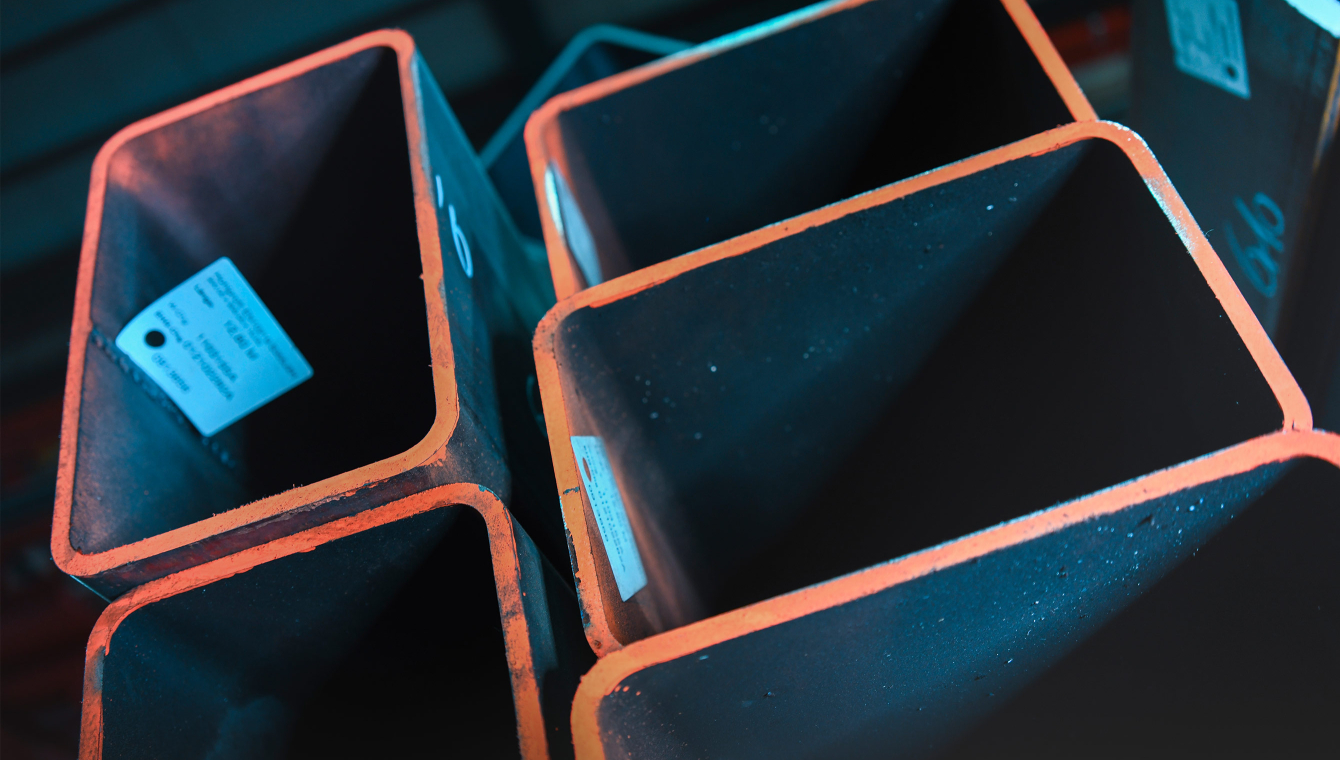

Weathering steel/structural steel is also known as corten steel (Corrosion-Resistance-Tensile strength). This is a higher strength weldable steel/structural steel with improved resistance to atmospheric corrosion. Its orange-brown colour, which develops over time, is due to the self-protective oxidation layer that forms naturally. Corten steel is used (often also for aesthetic reasons) for such elements as building façades, bridges, sculptures, signs and fire baskets. Our range includes weathering steels/structural steels as sheets.

Fine-grain structural steels/high-strength steels/structural steels

Steels/structural steels from this group are characterised by excellent strength properties and are largely used for heavily loaded components in lightweight construction, e.g. for crane booms, bridge components, machine frames and vehicle components. Fine-grain structural steel is high-strength and weldable. Our range includes fine-grain structural steels and high-strength steels/structural steels as sheets.

What are the properties of steel/structural steel?

Probably the most fundamental requirement for steel/structural steel or construction steel is its suitability for welding, because this is the most important joining technique in steel construction. Furthermore, this steel is generally:

- Relatively soft

- Very malleable (highly ductile)

- Very flexible (high tensile strength)

Steels/structural steels are used in their as-delivered condition. This means that no change in their microstructure takes place on site - the steel retains the properties given to it by the manufacturer. It is therefore very important that the correct steel/structural steel is selected, according to its intended use. Other characteristics are prioritised, depending on the group of steels. For example, weathering steel/structural steel (corten steel) is more corrosion-resistant than other grades, while fine-grained structural steel is stronger (yield strength > 350 MPa).

What is steel/structural steel made of?

Steels/structural steels are only characterised according to their mechanical properties, i.e. a steel with the same designation may possess a significantly different chemical composition depending on the manufacturer and batch.

Unalloyed steel/structural steel (alloy content < 2%) or low-alloyed steel/structural steel (alloy content < 5%) with a maximum carbon content of 0.6% is most commonly used. The higher the carbon content, the less suitable the steel is for welding.

The fine grain in the structure of fine-grained structural steel is achieved by adding alloying elements such as chromium, nickel, titanium, niobium and vanadium, which increase the strength of the steel. Its carbon content is roughly 0.15%.

Visit our online shop!

Visit our online shop to find all the information you need on availability, dimensions and delivery conditions. Once you have registered, you will have constant access to the latest prices and you can purchase your steels and non-ferrous metals directly online.

Continue to shopFurther information about EHG steel/structural steel

Downloads/Brochures

Do you have any questions?

Are you looking for a specific quality or processing service, or are you interested in our services? Contact us today. We deliver solutions.