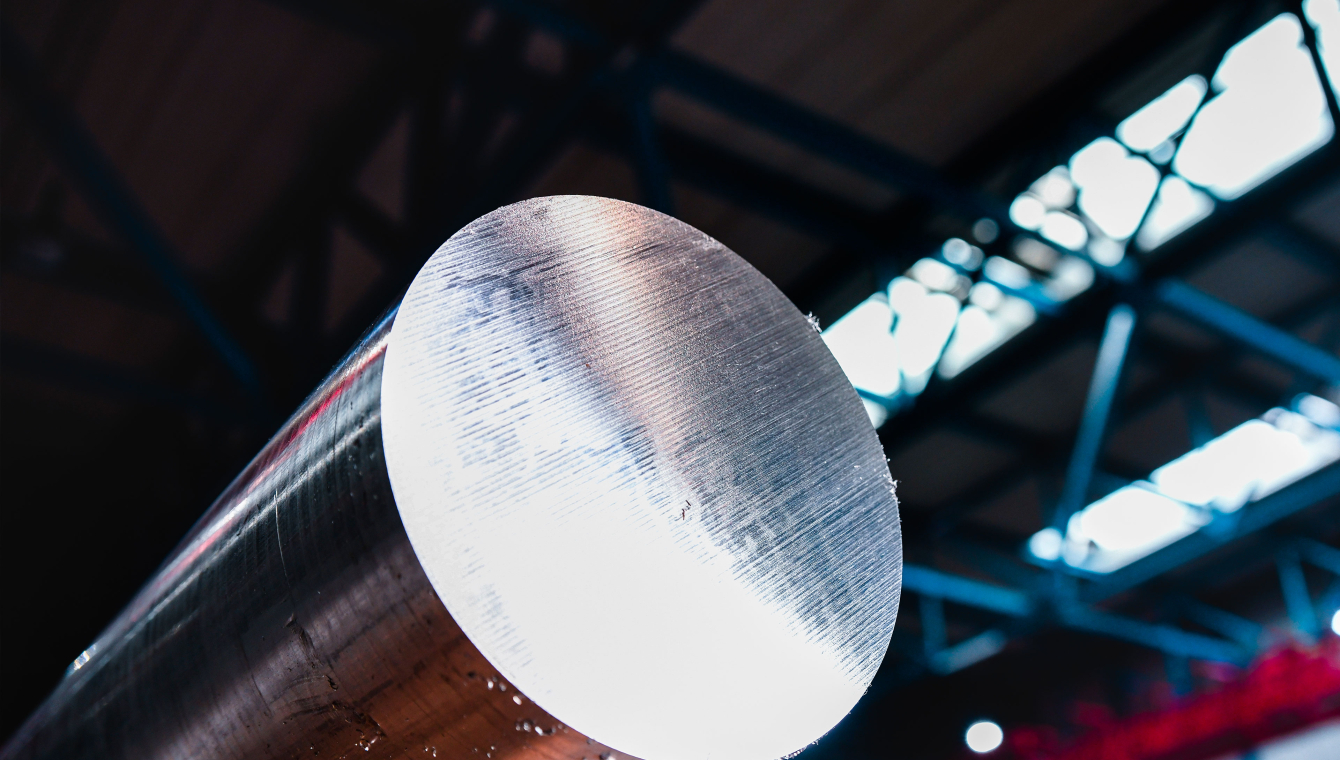

Processing services – Professional, high-precision steel and metal processing

With our modern machinery, we process the products precisely according to your wishes.

Sawing and cutting

We cut steel and metal precisely to length, in Europe's most high-tech cutting and sawing centre.

Learn moreTube laser cutting

Thanks to laser technology, we are able to saw, drill, mill and deburr steel and metal in a single process step.

Learn moreFriction drilling

Using modern equipment, we realise chipless passages in thin-walled profiles.

Learn moreEdge and surface finishing

We deliver metal blanks deburred and free of rust, scale and rolling skin. If required, we can also provide blanks preserved, lasered or barrel finished.

Learn moreWhat is stainless magnetic steel used for?

Magnetic stainless steels are used wherever the magnetic property or the increased thermal conductivity is desired, or where these characteristics are not problematic. Martensitic steel is used when additional high strength and hardness are required, as in the production of knives or tools.

Stainless magnetic steel is used for applications including the following:

- Exhaust systems, solenoid valves, electric injection, magnetic sensors in the automotive industry

- Cookware for induction cookers

- Valves and turbine parts in power plants

- Knife gate valves, ball gate valves, check valves and shut-off valves in water management, the oil and natural gas industry

What are the properties of stainless magnetic steel?

The characteristics of magnetic stainless steel vary depending on the microstructure.

Ferritic steel

Steel with this structure is magnetic and, depending on the chromium content, inert or resistant to corrosion. It can be welded to a limited degree, because it becomes brittle when exposed to heat for an extended period of time. Ferritic steel can only be cold formed.

Martensitic steel

This steel is also magnetic, depending on the carbon content. It can be hardened through heat treatment and can reach high hardness values depending on its composition. Martensitic steel is resistant to corrosion, although its increased carbon content makes this property less distinct than in other grades of steel. Welding is only possible to a very limited extent.

Austenitic steel

These steels are not (or are only weakly) magnetic. You can find more information on this type of steel on our standard stainless steel page.

What is stainless magnetic steel made of?

Like other stainless steels, stainless magnetic steel consists of an iron-chromium alloy and is also known as chrome steel. Different grades are created by varying the chromium content and adding other alloying elements. Whether a steel is magnetic or not is determined by its structure.

Ferritic stainless steels contain a high chromium and low carbon content. The proportion of nickel is very low and often even non-existent. The chromium content varies and other elements such as niobium, titanium or molybdenum may be added, depending on the desired property.

Martensitic stainless steel contains a slightly lower chromium content than ferritic grades. Martensite is formed by the rapid cooling of austenite. Martensitic steel is magnetic and frequently contains other alloying elements such as vanadium or molybdenum.

Visit our online shop!

Visit our online shop to find all the information you need on availability, dimensions and delivery conditions. Once you have registered, you will have constant access to the latest prices and you can purchase your steels and non-ferrous metals directly online.

Continue to shopVorname Nachname

Position

Further information on EHG stainless steel products

2,500 tonnes in stock in 3,000 dimensions

Downloads/Brochures

Do you have any questions?

Are you looking for a specific quality or processing service, or are you interested in our services? Contact us today. We deliver solutions.