Processing services – Professional, high-precision steel and metal processing

With our modern machinery, we process the products precisely according to your wishes.

Sawing and cutting

We cut steel and metal precisely to length, in Europe's most high-tech cutting and sawing centre.

Learn moreTube laser cutting

Thanks to laser technology, we are able to saw, drill, mill and deburr steel and metal in a single process step.

Learn moreFriction drilling

Using modern equipment, we realise chipless passages in thin-walled profiles.

Learn moreEdge and surface finishing

We deliver metal blanks deburred and free of rust, scale and rolling skin. If required, we can also provide blanks preserved, lasered or barrel finished.

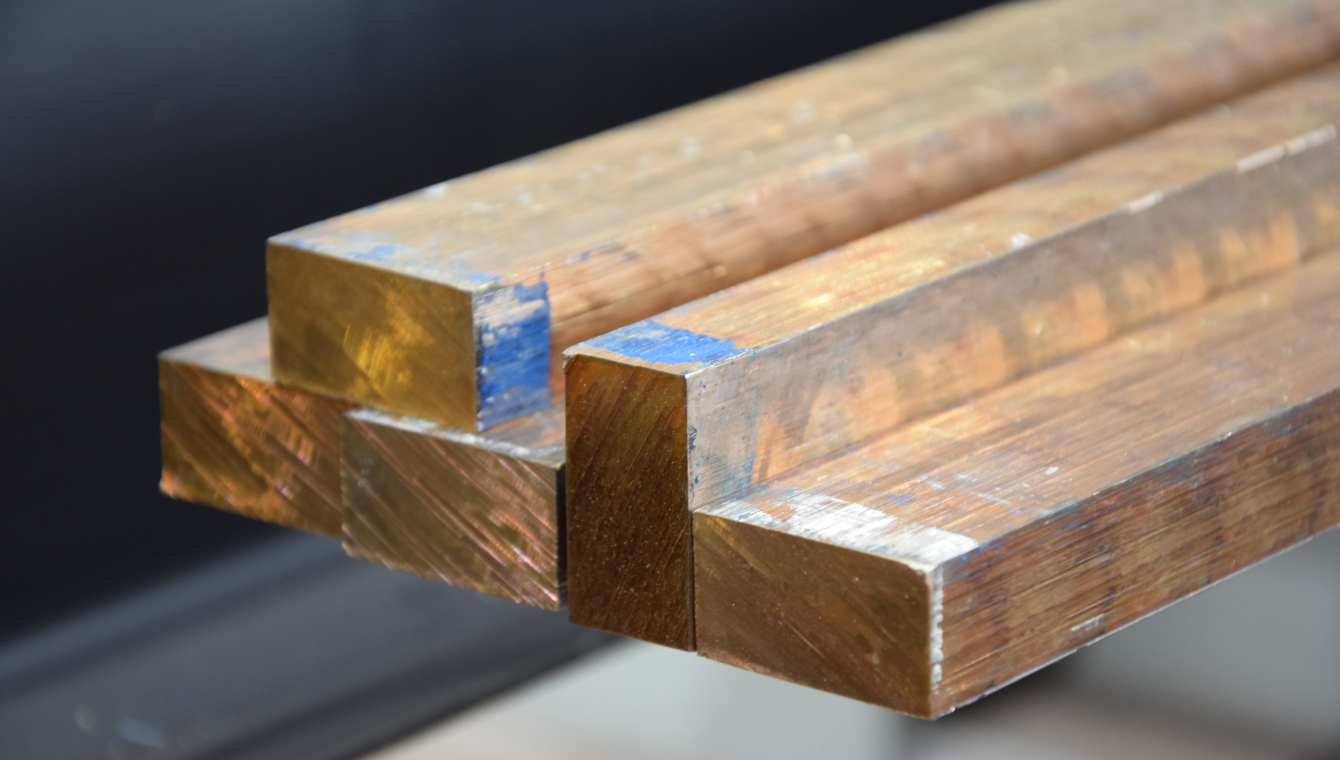

Learn moreWhat is bronze used for?

Bronze is used in numerous areas. The alloy is made into bells, jewellery and life-size statues, and is also found in instruments such as drums. Bronze medals are commonplace at competitions, for example. In addition to these more traditional applications, bronze is also used in industry, for example for:

- Axle bearings

- Compound casting and mould casting tools

- Propellers

- Springs

- Balance beams

- Overhead lines

- Power installations

- Plain bearings

- Valves

What are the properties of bronze?

The alloy component tin gives bronze its high strength and hardness. The alloy is corrosion and wear resistant, as well as being electrically and thermally conductive. The conductivity decreases with increasing tin content. Bronze offers good spring and sliding properties and exhibits excellent fatigue strength. The properties of bronze can be influenced by its alloy components and their proportions:

- Aluminium bronze contains iron as well as aluminium. The composition makes the material elastic, resistant to seawater and wear, and slightly magnetic.

- Lead bronze delivers corrosion resistance and good sliding properties.

- Manganese bronze is characterised by high corrosion and heat resistance.

- Phosphor bronze is highly impermeable and very strong.

What is bronze made of?

The collective term bronze is used to describe alloys of the non-ferrous metal copper with other metals, such as tin. Alongside two-material alloys, multi-material alloys are also common. This allows the material properties to be specifically influenced.

Metallurgically, the term bronze is only used together with the prefixed main alloying addition. The most familiar bronze alloys include:

- Tin bronze

- Aluminium bronze

- Lead bronze

- Manganese bronze

- Phosphor bronze

A further common classification of bronze is its subdivision according to processing. A distinction is made between wrought and cast alloys.

In wrought alloys, the bronze cast into ingots is further shaped to produce the desired bronze semi-finished product. Hot rolling, bending, edging, drawing and extrusion techniques are used to produce bronze strips, bronze sheets, bronze wire and much more besides.

The advantage of cast alloys is that the desired workpiece can be cast ready for final moulding or close to final moulding, which saves time in production.

Visit our online shop!

Visit our online shop to find all the information you need on availability, dimensions and delivery conditions. Once you have registered, you will have constant access to the latest prices and you can purchase your steels and non-ferrous metals directly online.

Continue to shopVorname Nachname

Position

Further information on EHG aluminium and non-ferrous metals

2,000 tonnes of aluminium and non-ferrous metals in stock in 3,000 dimensions

Downloads/Brochures

Do you have any questions?

Are you looking for a specific quality or processing service, or are you interested in our services? Contact us today. We deliver solutions.